the future is now

Take chocolate manufacturing to the next level and create unique chocolate designs that could not have been done before.

our campaign is over

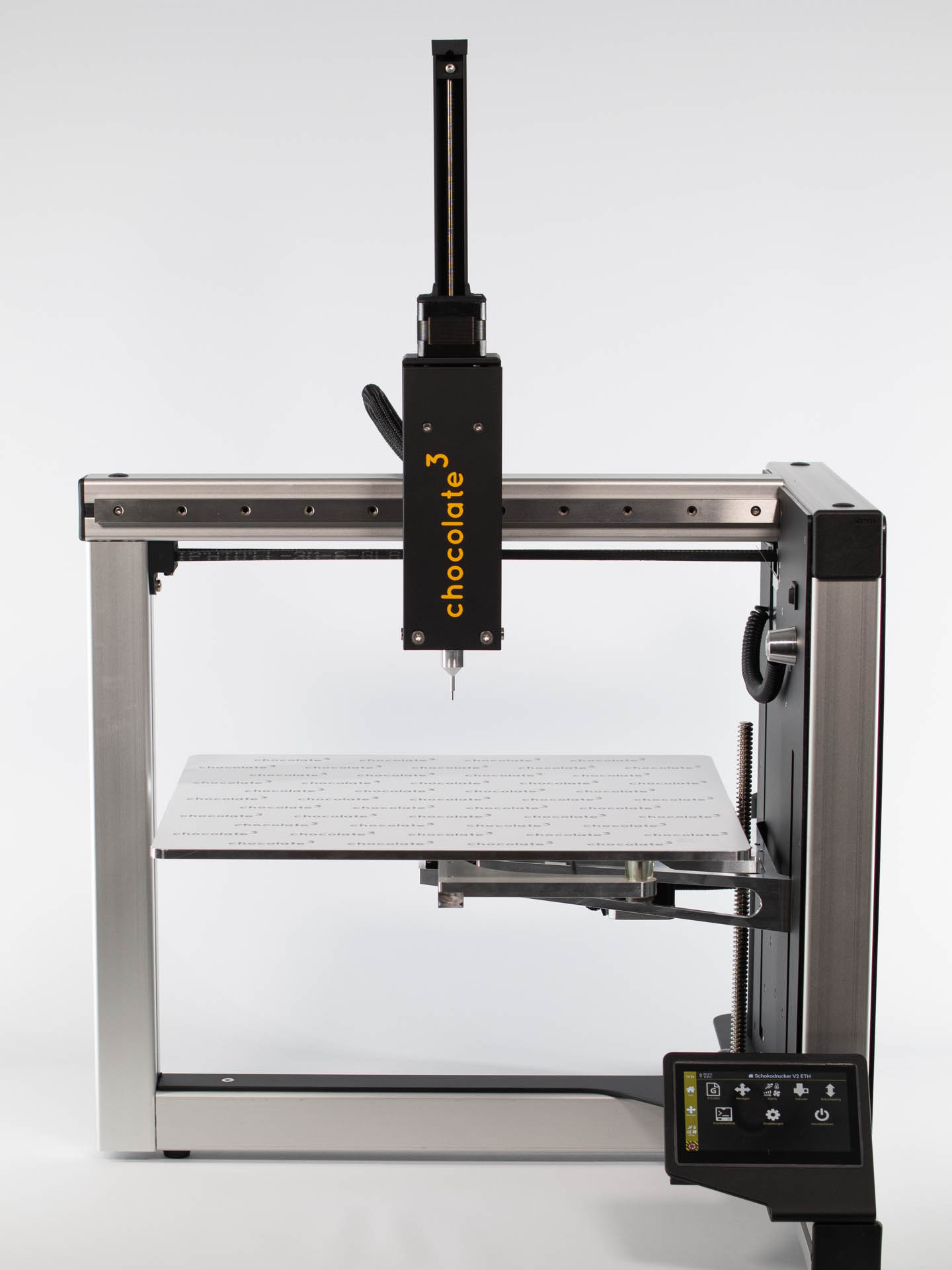

but you can still take a lookWe truly believe 3d printing chocolate does not have to be difficult. With the choc mate 2 we have simplified the process of printing and designing artisanal chocolate, so anyone can do it!

Start shaping the future of chocolate!

precise

Repeatability in every layer, every print and every day.easy to use

No manual tempering needed.rational

Less interaction thanks to a large print bed.reliable

Because you can do more than watch your printer.limitless

If you can think of it, you can do it!Quiet

Super silent operation to keep you calm when working next to it.we did it again.

After the incredible success and support for our first campaign in 2018, we decided to do it again.

Back then we sold the first iteration of our chocolate printer, and have customers asking for it ever since.

This is why we decided to develop a second generation, which extends the initial design even further and greatly improves usability.

Our second campaign was a huge success and we we have backers from all over the world.

chocolate³

Korbinianplatz 2

85737 Ismaning

Germany

features

everything that makes the choc mate differentWe truly believe we can offer the optimal solution for printing artisanal chocolate. But what makes us stand out?

Our printers have been delivering high quality results for more than 3 years - even under high intensity load. In this, we have and stay commited to continuously improving our products and processes.

Over time we learned it is not only chocolate prints many of our customers are seeking, but the ability to do it themselves.

This is why we created the second generation of our choc mate.

made in germany

Developed and designed in Germany. Assembled and tested by ourselves. Sourced with a focus on regional products.built to last

Built with industrial grade components, the choc mate is built to withstand 24/7 use for uninterrupted production.super silent operation

Trinamic stepper drivers keep noise to a minimum so you can work close.designed for speed

Combining magnetic built plates and an integrated preheater with sequential printing leads to less interaction time.food safety

The choc mate is not a modified 3D printer but designed from scratch for food safety, food hygiene and easy cleaning.easy operation

No CAD, no manual slicing, and no complicated menus. The choc mate is designed to make operation as easy as possible!precise temperature control

Two separate temperatures for precision down to 0.1° C. We will keep your chocolate tempered!wireless connectivity

Wireless file upload and control to make things simple and keep your workplace clean.precise

With nozzle sizes down to 0.5 mm you can print the finest details while the printer even compensates for uneven surfaces.automated tempering

When using our chocolate sticks no manual tempering is needed.also take a look at our tv spot

(german audio)automated tempering

When using our chocolate sticks no manual tempering is needed. They are available in dark (vegan) , milk and white chocolate from Felchlin.On request, they can also be made from your custom chocolate.

printing any chocolate

We challenged ourselves to not use any "special" 3d-printing chocolate or compound chocolate, but make it possible to use any artisanal chocolate.on printer control

We tightly integrated a capacitive 4.3" touch display for fast, reliable and intuitive control without any extra devices.Remote web based control from any other device will keep you flexible if needed.

based on leading components

The choc mate 2 is built with item construction profiles, misumi linear rails and machined high strength aluminium parts. It utilizses a duet3d control board and repetier server.custom slicing

Because chocolate is not plastic, different settings are needed to achieve perfect results. This is why we created our custom designing and slicing solution.guided interaction

Because we think a pastry chef does not need to be a 3d printing expert, we automated most steps while guiding you through the steps you might want to choose for yourself.perfect printing

Changing nozzles usually means variation in height. To keep things simple we automatically measure the nozzle height.chocolate bar mode

While chocolate hardens it shrinks and tends to curve. To still offer precision we optically measure the curvature and compensate for it.technical specifications

All specifications are based on the current model and might change slightly.Build volume (W - L - H)

12.6 liters

Printer size (W - L - H)

(inactive) - 483x468x718 mm

(active) - 483x545x718 mm

Noise levels

peak 60dB

Power

100-240 V AC 50/60 Hz

60 W (max)

Connectivity

802.11 b/g/n/ac

RJ45 (10/100/1000)

USB-C | 2.0

Operation temperature

5-35°C for general operation

-10-50° C for storing

Certification

FDA planned

Weigth

12 kg

Packaging

about 19,5 kg

60 x 60 x 67 cm

team

meet the people behind the printer

Benedikt Daschner

Jan Sonnen

Christian Reil